At Cambron Engineering, we specialize in CNC machining that combines cutting-edge technology with decades of experience to deliver high-quality, precise parts. From OEM machining to carbon steel fabrication, our CNC machining services are tailored to meet the unique demands of industries like automotive, aerospace, and heavy manufacturing.

Our shop is set up to seamlessly handle complex, one-off parts that require meticulous attention to detail, precision, and innovative solutions. Whether it’s machining of metal fabrications, or handling tight tolerances and specialty finishes, we have the expertise to deliver outstanding results.

As a one-stop shop for CNC machining, we manage every step of your project in-house. From design and blueprint analysis to the machining, finishing, and inspection, Cambron does it all. This approach not only reduces delays but also ensures superior quality control, precision, and delivery timelines.

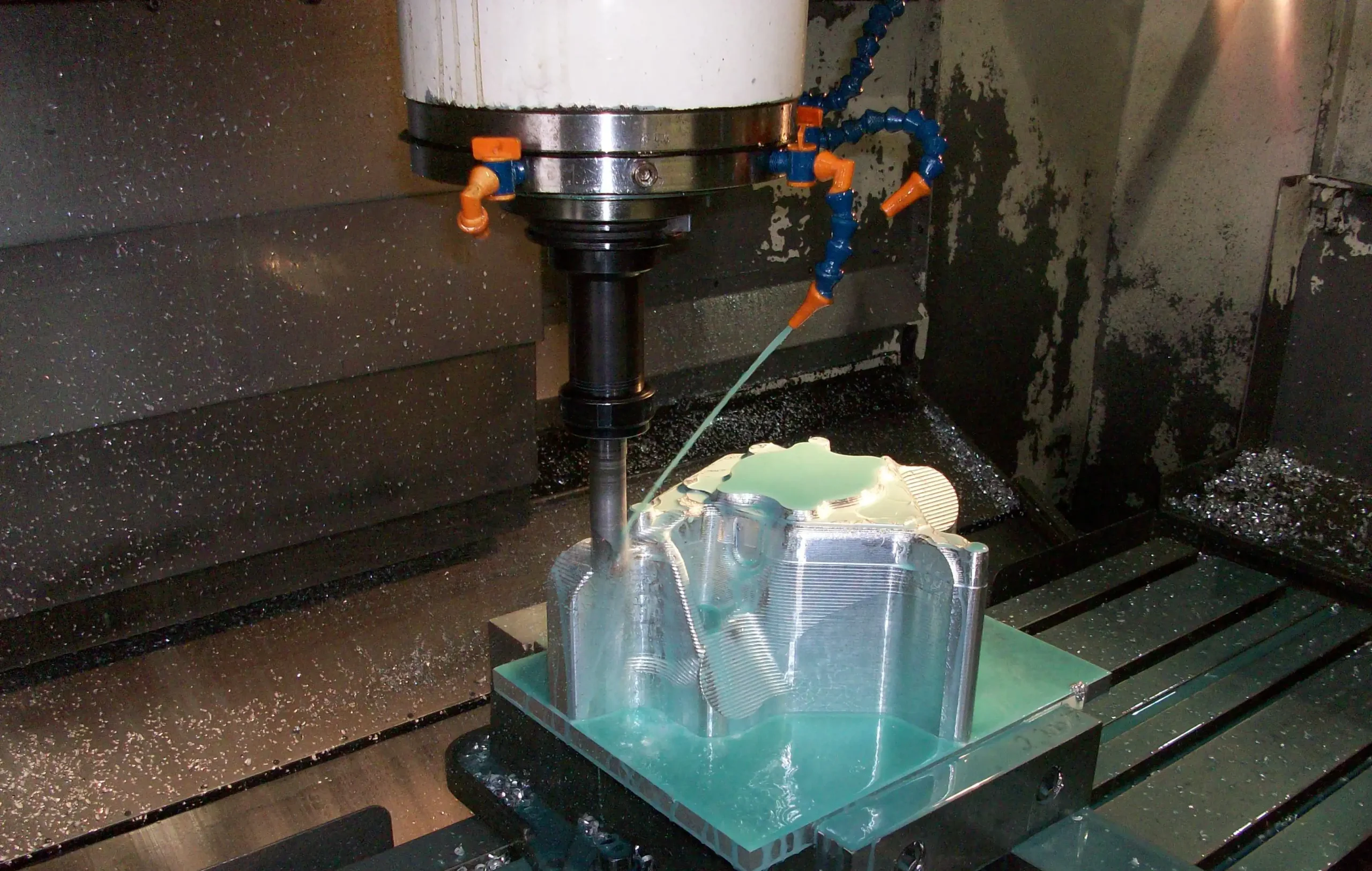

We use advanced CNC machining centers to handle everything from the most intricate parts to large-scale fabrications. Our machines can work with a wide variety of materials, including carbon steel, high-nickel alloys, and more, ensuring that we can meet the specific requirements of your toughest projects.

We’re always investing in the latest CNC equipment to stay at the forefront of machining technology. Our machines include Okuma CNC machining centers with 4th axis capabilities, advanced CNC turning, as well as vertical turning machines, and CNC wire EDM for high-precision cutting. Automation capabilities mean we can run machines overnight with remote monitoring, shortening lead times and reducing costs.

Our CNC machines deliver faster, more efficient production times compared to traditional machining methods, and our ability to run continuous production with minimal oversight means we can meet tight deadlines without compromising on quality.

We thrive on the projects that other machine shops shy away from. Whether it's machining parts with tight tolerances, difficult-to-machine materials, or complex fabrications, we have the technology and expertise to get the job done right.

Our CNC Wire EDM can even cut through hardened parts with ease, saving time on certain components that other methods would struggle with. We take on OEM machining projects that demand high-precision parts and OEM metal fabrication that require both technical skill and advanced machinery. From prototypes to small-scale production, we ensure your parts are manufactured to the exacting specifications of your design.

We invest in the latest and most specialized CNC equipment to handle the toughest projects. Our cutting-edge machinery ensures we meet even the most demanding specifications with precision and speed. With our advanced CNC machines, we’re capable of taking on large, complex parts and machining intricate shapes with high precision and speed.

Our CNC vertical turning centers provide high-precision machining for large, heavy parts. These machines are ideal for turning components with large diameters, offering efficient, precise results in a vertical setup. Equipped with live tooling, they allow us to perform both turning and milling operations in a single setup, saving valuable time while maintaining accuracy.

With capabilities in CNC grinding, including I.D. and O.D. grinding, we achieve precision finishes on components with tolerances as tight as .0001”. Our CNC Wire EDM machine can handle parts up to 20” tall, cutting through even the hardest materials to form precise shapes, contours, and internal features.

Machining is just one facet of what we offer at Cambron Engineering. We perform all of our services in-house, saving you time and money for complex parts that require multiple processes.

At Cambron Engineering, we pride ourselves on being a reliable partner for all your machining and fabrication needs.

Whether you’re in automotive, aerospace, or heavy manufacturing, our expertise in CNC machining, precision metal components, grinding, and custom tooling makes us your go-to solution for high-quality parts produced efficiently.

With over 50 years in the industry and a commitment to employee ownership, we ensure that your project is handled with care, precision, and the attention it deserves. As a one-stop shop, we handle everything from consulting on your design to machining, welding, and finishing, saving you time and hassle by keeping everything in-house.

If you’re ready to discuss your project, get a quote, or have any questions, please reach out to us using the form below. We’re here to help and look forward to partnering with you on your next project.