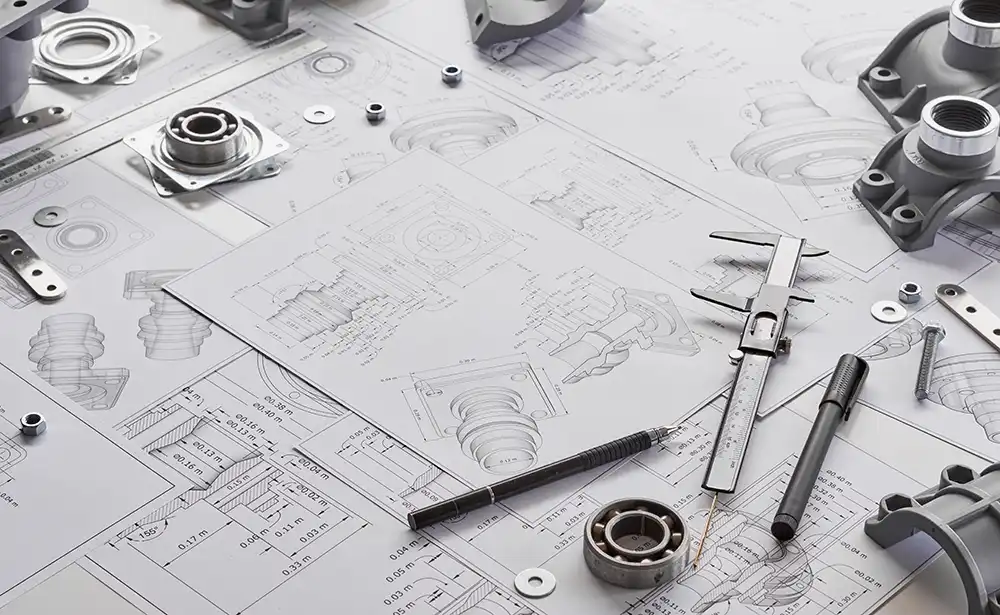

Additional Services for Precision Components

Where Complexity Meets Craftsmanship

Your One-Stop Shop for Precision Machining Solutions

Cambron Engineering offers a comprehensive range of services that make us your go-to partner for all things machining, especially for tough projects or components with complex shapes. Whether you’re in need of precision metal components, wire EDM, welding, or die repair, we handle everything in-house. By offering a wide array of services, we save you time, money, and effort by keeping your entire project under one roof.

We also serve as a third-party contractor for other machine shops, providing capabilities they may not have in-house. We take pride in delivering high-quality metal parts with our cost-effective services.

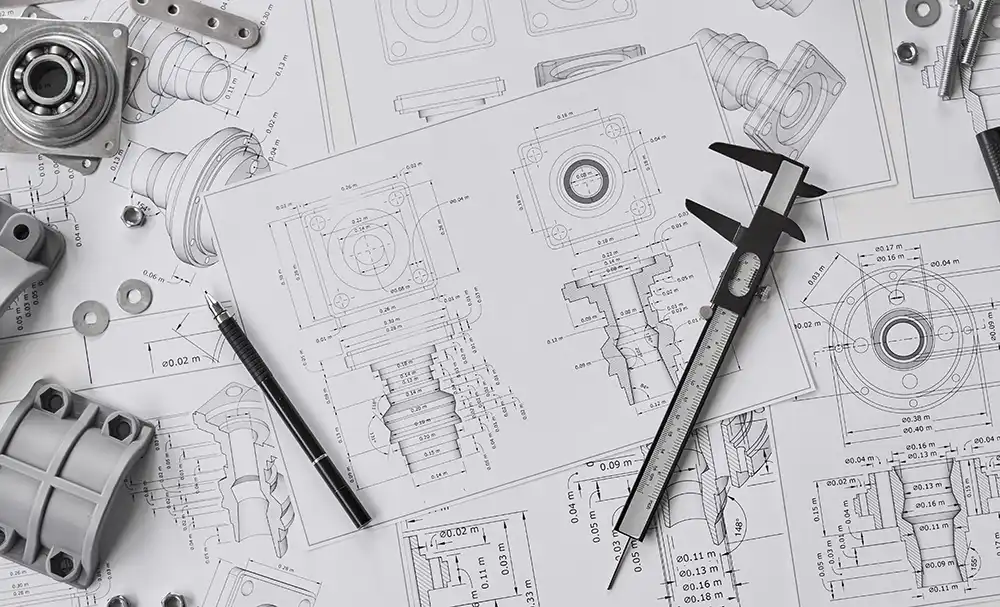

Engineering & Consulting

Our services go beyond standard machining. We specialize in the building of tooling, gauges, dies, small machines, and fixtures, and can also handle plastic molds and die-cast dies.

We offer detailed consulting services to assist with challenging parts. If a blueprint arrives that’s particularly complex or difficult, our team works directly with you to determine the best course of action and how we can meet your machining needs using our capabilities.

This consulting service is part of our commitment to being a true one-stop shop, handling all aspects of your project from design to completion.

MIG, TIG, and Stick Welding

While welding is a standalone service we offer, it truly shines when integrated into our complete one-stop shop approach. We regularly incorporate welding into larger projects, ensuring that every aspect of your part is handled efficiently and to the highest standard.

Our certified welder has extensive experience in various welding techniques, including Stainless Steel 3G GTAW AWS and Aluminum 3G GTAW ATAW, and can tackle even the toughest jobs with precision.

When welding is part of your larger project, we streamline the process, reducing both lead times and costs.

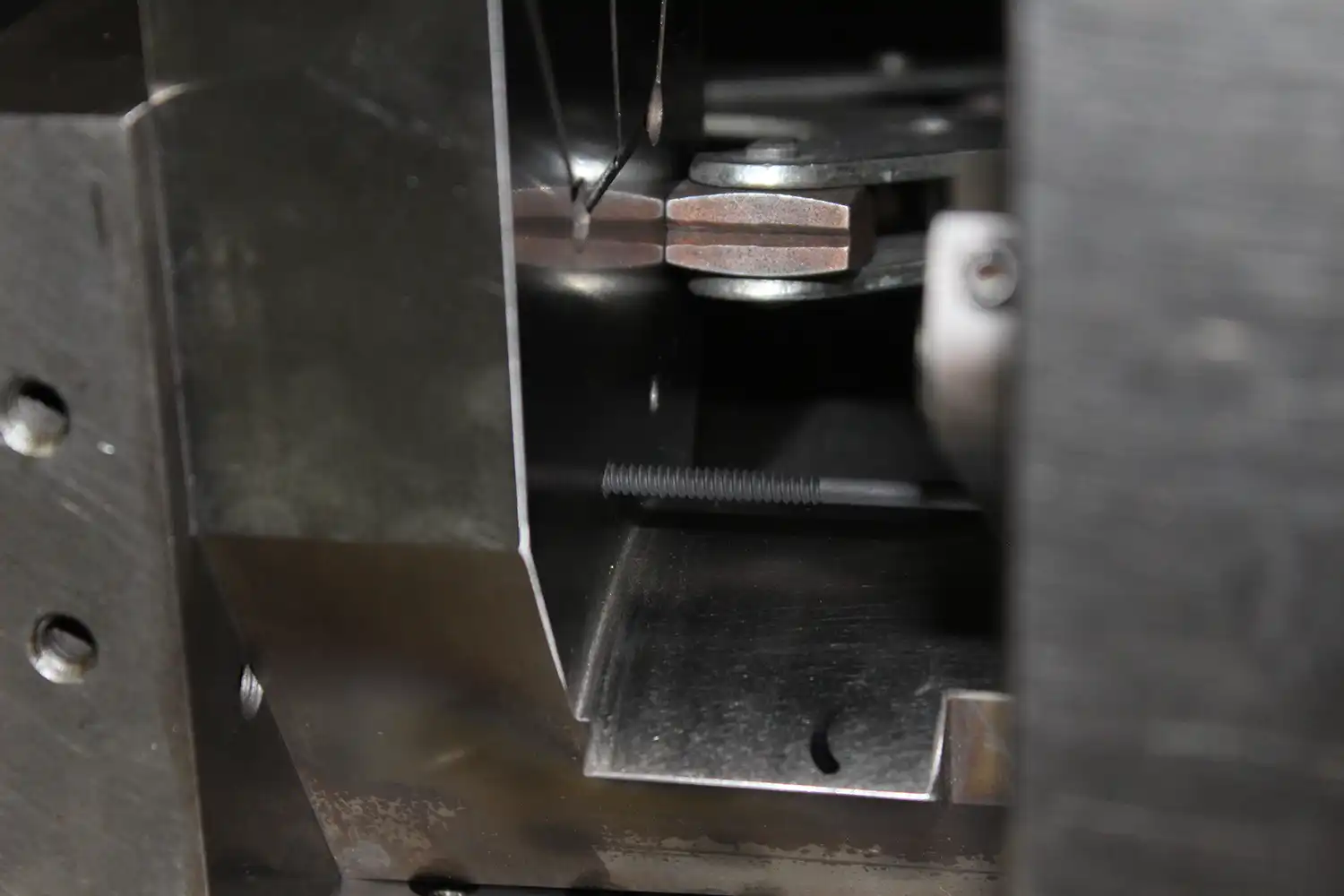

Fabrication and Die Repair

We offer fabrication services and can repair damaged dies. If your die becomes damaged, simply ship it to us, and we’ll repair it and ship it back to you.

This service, paired with our welding capabilities, ensures that your tooling is restored and ready to go with minimal downtime.

We’re ready to handle the work that other shops may shy away from.

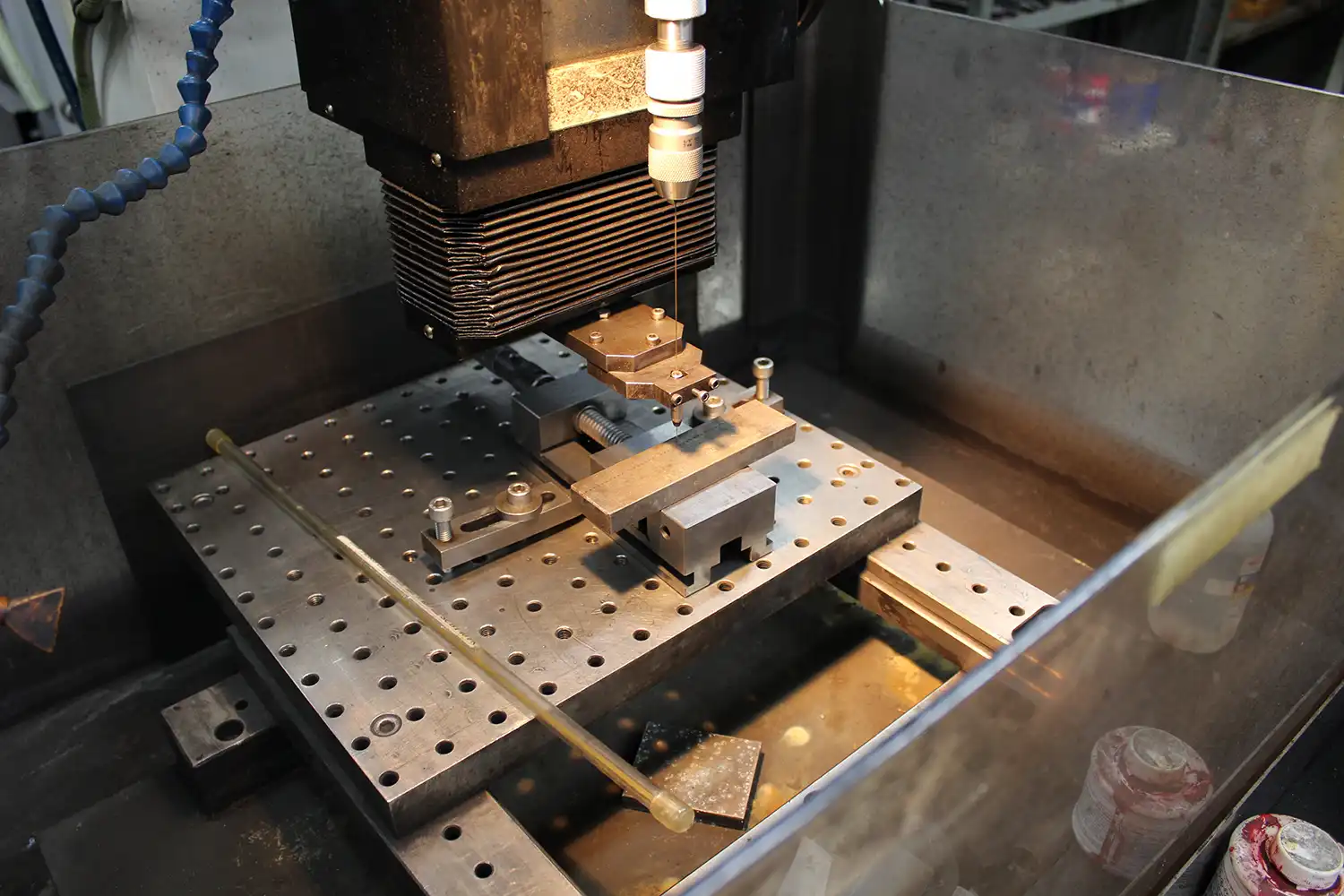

Tap and Drill Removal

Have you ever broken a tap or drill in a part? We offer a specialized tap and drill removal service using EDM technology to remove broken taps or drills from parts, saving you the cost of remaking the entire part.

This service is particularly valuable for other machine shops working on expensive or complex parts.

We can safely remove the broken pieces, re-tap the hole, and restore the part to its original specifications, saving you both time and material costs.

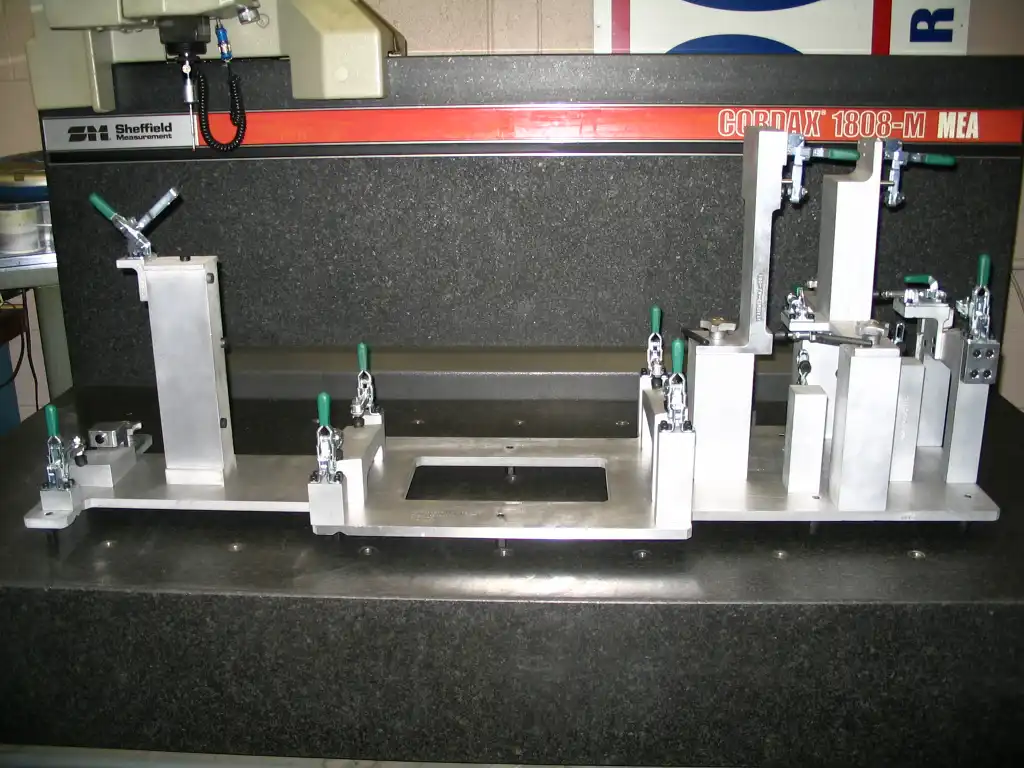

CMM Inspection and Certification

Our CMM inspection system allows us to provide precise inspections and generate detailed inspection reports – critical for parts with tight tolerances.

While we’re not a third-party inspection service, our use of CMM ensures that every part we produce meets stringent quality standards.

Our ISO certification also reinforces our commitment to delivering defect-free parts that exceed your expectations.

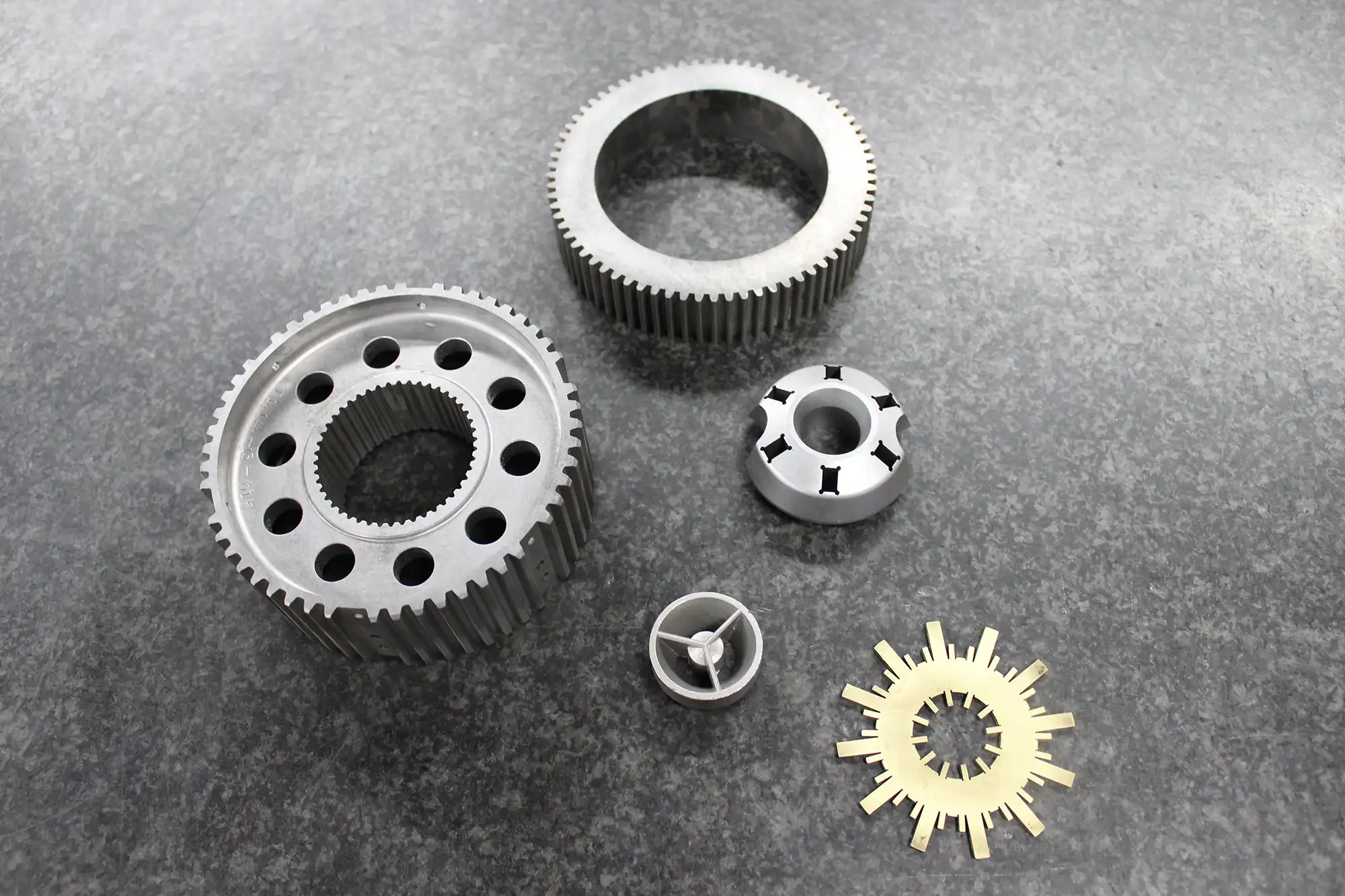

What We Can Produce

Cambron Engineering offers a wide range of capabilities, including the production of:

- Gears

- Prototypes

- Special Machinery

- Molds

- Keyseating

- Tool Dies

- Gages

- Assemblies

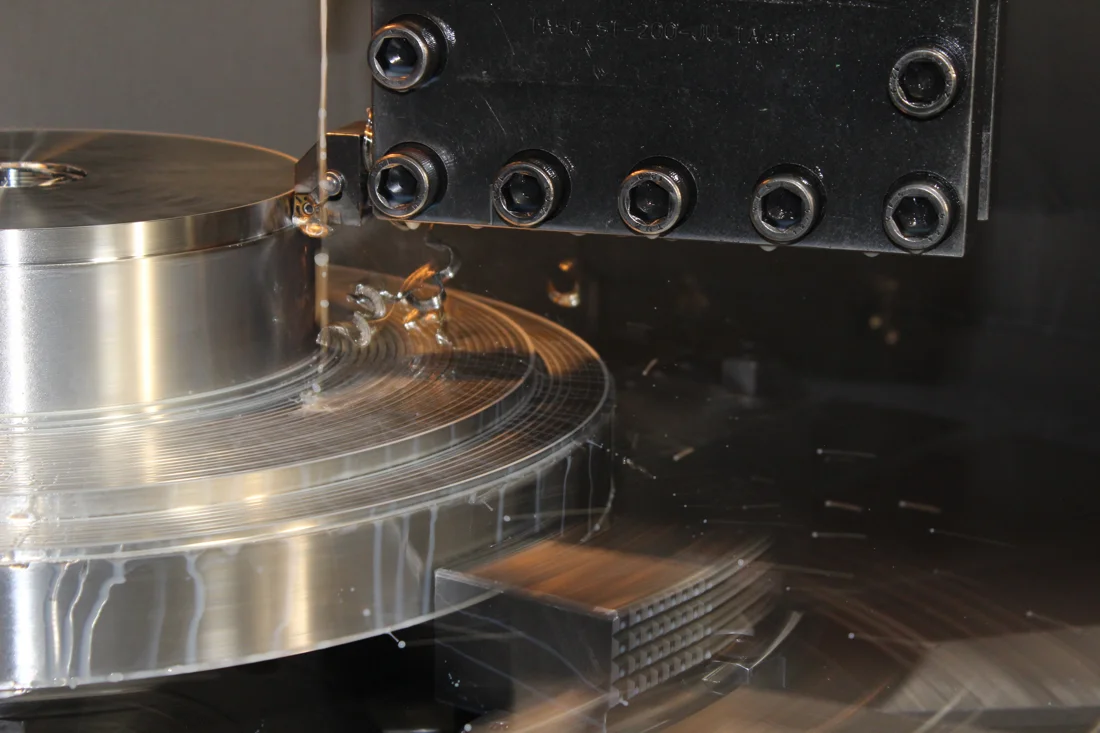

CNC Machining and Grinding

Cambron Engineering offers comprehensive machining and grinding services, which often serve as the foundation for our additional services.

How We Work with You

When a blueprint arrives, we don’t just start machining – we take the time to consult with you to understand your needs. Whether in person, over the phone, or during a site visit, these in-depth conversations ensure we’re aligned on your expectations.

Many of the parts we manufacture go through seven or more processes, including turning, milling, welding, grinding, and quality control. We manage all of these processes in-house, ensuring seamless production and the highest quality parts.

By engaging directly with you, we save you time, eliminate surprises, and provide solutions that are tailored to your needs. This proactive approach is what sets Cambron Engineering apart, making us a true partner in your success.

Get in Touch

At Cambron Engineering, we pride ourselves on being a reliable partner for all your machining and fabrication needs.

Whether you’re in automotive, aerospace, or heavy manufacturing, our expertise in CNC machining, precision metal components, grinding, and custom tooling makes us your go-to solution for high-quality parts produced efficiently.

With over 50 years in the industry and a commitment to employee ownership, we ensure that your project is handled with care, precision, and the attention it deserves. As a one-stop shop, we handle everything from consulting on your design to machining, welding, and finishing, saving you time and hassle by keeping everything in-house.

If you’re ready to discuss your project, get a quote, or have any questions, please reach out to us using the form below. We’re here to help and look forward to partnering with you on your next project.